Technical support for scientific studies

Our scientists have access to an extensive technical infrastructure at our institute. This supports them in carrying out studies and tests as well as in projects with industrial partners. We thus support all researchers in achieving meaningful research results quickly and competently.

- Vehicle axle test bench with highly dynamic hexapod - an efficient development and testing environment for mechatronic vehicle axles

- Laboratories for data transmission and sensor systems - Radio Frequency Lab and Photonic Lab for high-precision testing of state-of-the-art electronic and optoelectronic systems

- Business and Economic Research Laboratory (BaER-Lab) - experimental laboratory for researching economic issues using controlled laboratory experiments

- Interactive Driving Simulator - development platform for virtual prototyping of advanced driver assistance systems

- Innovation laboratory of the "Product Creation" specialist group - laboratory environment for investigating future changes in product development as a result of digitalisation

- Smart Automation Laboratory - production environment for development in the factory of the future

- Software tools - tools for analysing and developing attack-proof software

Vehicle axle test stand with highly dynamic hexapod

Efficient development and testing environment for mechatronic vehicle axles

The increasing integration of chassis control systems can significantly improve the comfort and safety of modern vehicles. However, due to the high number of vehicle derivatives, the development of the electronic components contained requires the use of efficient test procedures. We are meeting this need by developing a universal test environment for mechatronic vehicle axles.

Hardware-in-the-loop simulation

The axle test bench at the Heinz Nixdorf Institute provides a development environment for carrying out mechatronic hardware-in-the-loop (HiL) simulations. Only the test specimen, in this case a mechatronic vehicle axle, is actually set up on the test bench. The so-called "residual vehicle model", which represents all other vehicle components, is simulated on a real-time computer. Finally, the real and virtual subsystems are linked by the test bench actuators and sensors. As all comfort, safety and dynamics-relevant components of a vehicle are either real or virtual in the laboratory, driving tests can be simulated. Active chassis components, such as roll stabilisers, can be tuned and functionally validated in a resource-saving manner within this framework. The aim is to minimise the number of costly road tests and replace them with time and cost-efficient laboratory tests under reproducible test conditions.

Iteration-free fatigue strength testing

Another branch of research at the Heinz Nixdorf Institute is dedicated to optimised fatigue strength testing (BFU). This is based on the realisation that the control bandwidth of conventional axle test rigs is not sufficient to achieve the accuracy required for BFU when reproducing predefined stress spectra (target signals) in a direct link to the target. Instead, the actuating signals of the individual actuators must be taught in iteratively. This can result in pre-damage to the test specimen and thus falsify the test results. The combination of new control methods with the dynamically optimised test bench hardware, on the other hand, makes it possible to increase the control bandwidth to such an extent that the target signals can be directly controlled and no time-consuming iteration of the control signals is required.

Laboratories for the data transmission and sensor systems of the future

High-precision investigation of state-of-the-art electronic and optoelectronic systems

Integrated circuits and systems are developed and subsequently tested under laboratory conditions in the "Circuit Technology" department. The investigation and characterisation of ultra-low-power, high-frequency and electro-optical chips requires complex measurement methods and high-end equipment.

Characterisation of electronic systems in the RF-Lab

In the Radio Frequency Lab (RF-Lab) of the "Circuit Technology" department, small structures in the micrometre range on microchips and high-frequency boards can be contacted using a wire bonder and the entire systems can then be examined on a wafer prober. Vector network analysers, high-frequency oscilloscopes and various other logic analysers and high-frequency signal generators as well as other high-frequency measurement technology are available to examine high-frequency modules and chips at frequencies and data rates of up to 125 GHz and 256 GB/s respectively. This means that state-of-the-art radar systems, receiver and transmitter circuits for wireless and wired communication systems, frequency synthesisers and much more can be tested experimentally with regard to their performance and functionality.

High-precision investigations in the photonic lab

There is also an adjacent photonic lab, which contains an optical table for complex optical setups and a large selection of optical components, such as glass fibres, 1550 nm laser sources, optical couplers, fibre arrays, power detectors, RF photodiodes, coherent receivers, programmable optical filters, optical modulators, spectrum analysers and much more. The laser laboratory also contains a mode-locked laser, an optical amplifier and the associated safety devices and protective equipment. Within the Photonic Lab, the latest monolithically integrated silicon photonic systems, i.e. silicon chips containing both electronic and optical components, are measured and analysed.

Selection of laboratory equipment:

- Wire bonder (Hesse Mechatronics Bonjet BJ653)

- Wafer prober (Signatone mm-Wave Probe Station)

- Vector Network Analyser (Anritsu VectorStar MS4647B)

- Real-time oscilloscope (Keysight UXR0702A)

- Arbitrary Waveform Generator (Keysight M8194A)

- RF photodiodes (Finisar XPDV3120, BPDV3120R)

- Waveshaper (II-VI 4000A)

- Spectral analyser (Yokogawa AQ6370D)

- Mode-lock laser (MENHIR Photonics M1550)

Business and Economic Research Laboratory (BaER-Lab)

Research into economic issues using controlled laboratory experiments

Experimental economic research investigates how people behave in economic decision-making situations. Paderborn University's economics experimental laboratory, the BaER-Lab, offers its researchers the opportunity to collect the necessary observational data through controlled laboratory experiments and thus empirically investigate relevant economic issues and theories.

Experimental economic research is based on the collection of observational data in order to better understand human behaviour in economic contexts. In doing so, it addresses the basic problem of empirical (economic) research, namely that there is hardly any data available on many economic issues or that data collection, for example in real companies, can only be realised with great effort, if at all. Experimental economic research is therefore a valuable method for collecting data via controlled laboratory experiments. In these experiments, participants make decisions on the computer in the context of a specific economic situation. Similar to clinical studies, only a single variable is changed between two groups of test subjects in an economic experiment, so that differences in observed behaviour can be attributed to precisely this one change. In contrast to psychological experiments, the participants must not be deceived. The participants are remunerated monetarily depending on their decisions. Due to the pandemic, the implementation of economic laboratory experiments had to be paused for some time. In the meantime, the technical infrastructure of the BaER Lab has been modernised and the existing computer-screen combination has been replaced by thin clients. In addition, online experiments were established in which participants can take part from the comfort of their own homes. Since the beginning of the winter semester 2022/23, laboratory experiments have been possible again in presence and have already been carried out in large numbers. The additional option of online experiments is to be retained. Current experimental projects deal with human behaviour in human-machine interactions, whistleblowing, risk assessment in financial decisions, reputation systems in online markets, the development of incentive systems in companies and the role of ethical principles in the economic context. With its 35 networked computer workstations, the "BaER Lab" is one of the largest economic experimental laboratories in Germany. There are currently almost 2,500 students in the lab's own online database, from which participants are recruited for the one- to two-hour experiments.

Interactive driving simulator at the Heinz Nixdorf Institute

Development platform for virtual prototyping of advanced driver assistance systems

The energy efficiency, safety and comfort of motor vehicles are increasingly characterised by advanced driver assistance systems. At the same time, however, the complexity of these systems is also increasing, which has an impact on the accompanying development process. Interactive driving simulators are a key technology for investigating the interaction between driver and assistance system under reproducible and safe test conditions.

Technological impulses such as e-mobility and automated driving are leading to a steady increase in the interconnectivity and multifunctionality of modern driver assistance systems, the development of which presents car manufacturers and suppliers with new technological challenges. In this context, the use of interactive driving simulators is an indispensable tool for supplementing the conventional development process with model-based methods. Simulative approaches offer the advantage of being able to analyse and optimise relevant system functions at a very early stage of development and without the cost-intensive construction of physical prototypes. At the same time, driving simulators provide access to a wide range of investigations from physiological and psychological perspectives, such as the design of human-machine interfaces, the testing of safety concepts or the interaction between the driver and assistance systems. This enables resource-efficient and significantly shortened innovation cycles to be realised.

In line with this guiding principle, the existing research infrastruture at the Heinz Nixdorf Institute is being supplemented by an interactive dynamic driving simulator. This has a unique motion system that uses innovative control algorithms to bring the virtual vehicle movements to life for the occupants in the simulator. The simulated environment is visualised by a computer cluster that generates a circular projection with eight projectors around the vehicle as well as the corresponding images in the exterior and rear-view mirrors. The modular design of the overall system also makes it easy to replace the installed vehicle cabins (small cars, lorries). The interplay of different sensory perceptions creates a realistic driving impression during virtual test drives in the simulator.

In addition to the continuous further development of the driving simulator, the optimisation of high-resolution headlight systems with dynamic light functions and the testing of robust sensor technologies for highly automated driving in adverse weather conditions are key research priorities at the Heinz Nixdorf Institute.

Smart Innovation Laboratory

Laboratory environment for investigating changes in product development through digitalization

The Smart Innovation Laboratory of the "Product Creation" specialist group makes it possible to investigate the effects of digitalization on product development. To this end, innovative approaches in the areas of "strategic product planning", "innovation management", "systems engineering" and "digital and virtual product creation" are being researched.

Digitalization in product development should be viewed on two levels: On the one hand, it supports innovative processes in product development. Examples include generative development approaches or data-driven requirements elicitation. Secondly, it enables the development of smart products and product-service systems. The Smart Innovation Laboratory in Professor Iris Gräßler's department has a unique research infrastructure for this. Knowledge-intensive processes in the early phases of product development in particular, which often take place collaboratively, can be supported by suitable technical assistance systems. The major challenge here is the interplay between collaboration, visualization and analysis.

The lab includes collaboration and prototyping workstations for collaboration. This allows interdisciplinary development teams to work together on the model-based development of new prototypes. These tasks are also supported by the use of digital tools, such as multi-touch tables and displays. Visualization tools allow prototypes to be experienced and experienced immersively at an early stage. These include flexible head-mounted displays and VR treadmills. These virtual experiences can be supplemented by physical prototypes that are produced using additive manufacturing, for example.

One research focus of the specialist group is the question of how product developers will use digital tools in the future. Therefore, a central function of the large-scale research device is the integration of research data: Video recording with data synchronization and integration of smart devices enables new insights into human-technology interaction. Thanks to data networking, research data can be analyzed and evaluated in real time or afterwards. The flexible and modular structure of the new Smart Innovation Laboratory enables a situation- and topic-dependent configuration for specific test scenarios in product development. In combination with the established, adjacent "Smart Automation Laboratory", the entire product development process is mapped for experimental investigations.

Smart Automation Laboratory

Future-oriented research and development in the digital factory of the future

Digitalization, information and material circularity, human-robot collaboration and artificial intelligence: these topics represent innovative and sustainable products and production systems of the future. The focus of the research projects in the Smart Automation Laboratory of the "Product Creation" specialist group is the analysis of new technologies in intelligent decentralized production systems to solve current and future challenges.

"Cyber-physical production systems (CPPS) are highly flexible, adaptive systems that are networked via internet technologies. They enable a whole new level of decentralization and autonomy: flexible coordination takes place via internet-based communication with standards such as OPC UA. It includes machines, sensors, workpieces, operating resources as well as storage and transport systems. Within this new form of control, human-centered work design must also be taken into account. This is being researched in the Smart Automation Laboratory, for example, using adaptive assistance systems that adapt individually to the employee's abilities. Other relevant technologies being investigated within the laboratory are the digital twin, predictive maintenance, dashboards and machine vision.

The laboratory consists of two production cells (a lathe and a milling machine), two 3D printers and an assembly station. The cells are connected to a material flow system. The laboratory also has three different types of robots (gantry robots, industrial robots, collaborative robots), which are used for loading and unloading at the machines. In addition, new software systems are constantly being developed and expanded. When a new order is received in the system, it is assigned to a shuttle on the material flow system. Scheduling is then carried out by a decentralized production control system. For this purpose, each unit is equipped with embedded information processing, which takes over the monitoring and control and provides a communication interface that enables decentralized control and provides an interface for central monitoring systems. This allows the system elements of production to be networked, configured and centrally monitored independently (Plug & Produce).

Current research focuses within the laboratory environment are the integration of employees into production planning and control as well as the use of machine vision quality gates. Here, visual inspection is carried out automatically using artificial intelligence.

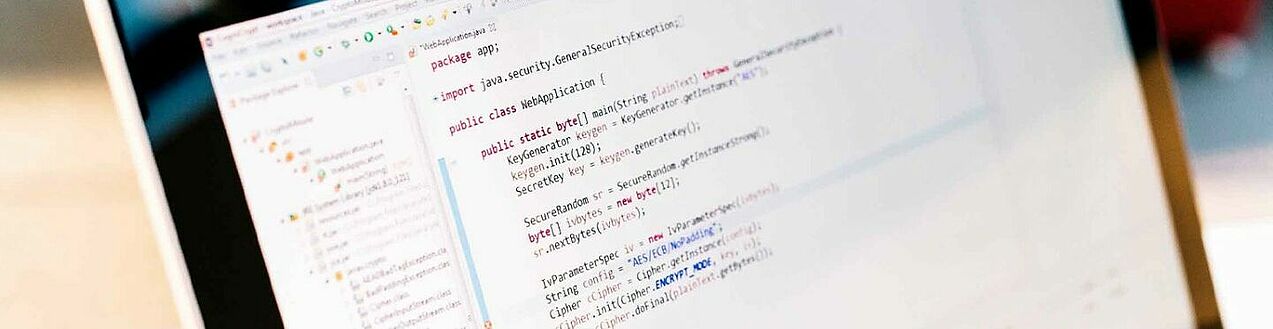

Software tools

In addition to physical infrastructure, the Heinz Nixdorf Institute also provides software tools that are used by hundreds of researchers at the HNI and around the world. Particularly prominent among these are tools that focus on the prototypical development of various supports for software developers. The Soot tool is the world's most widely used tool for automatic programme analysis for Java and Android applications. It was originally developed at McGill University, but since 2016 its further development has been driven forward under the leadership of the HNI. Soot has already been used several thousand times in scientific studies and has also been incorporated into commercial products.

The SootUp tool is a new edition of Soot with greatly improved architecture and usability. Its development was funded as part of a programme sponsored by the German Research Foundation for the sustainability of research software. The first release took place in 2022 and is intended to gradually replace Soot.

The Heros framework extends Soot, as well as other Java-based frameworks for programme analysis, with powerful functionality for so-called interprocedural programme analysis. This enables analyses to perform data flow analyses for an entire program using a mechanism that is very easy to extend, and to do so in parallel and very efficiently.

The FlowDroid tool is an extension of Soot that allows the simple analysis of data flows specifically for Android applications. FlowDroid is the scientific basis for several thousand scientific papers and is the most widely used Android analysis tool.

The requirements for programme analysis for C/C++ are very different from those for Java. For this reason, the PhASAR analysis framework was developed at the HNI specifically for analysing C/C++ source code. PhASAR is based on the open-source compiler framework LLVM and is also becoming increasingly popular in the research community and, like Soot, is also used in companies.

While all the software tools mentioned above are frameworks that researchers need to extend in order to do something useful, CogniCrypt is a directly usable software tool that allows developers to detect misuse of cryptographic software interfaces in Java or Android applications without further intervention or to proactively avoid them by generating code. This avoids security vulnerabilities in relation to cryptography at an early stage. CogniCrypt is an Eclipse Open Source project.

Overview of the software tools on the pages of the "Secure Software Engineering" specialist group