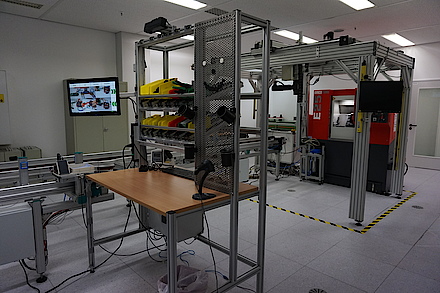

Smart Automation Laboratory

In the Smart Automation Laboratory, we put our vision of Industry 4.0 into practice. The laboratory is used directly for research and teaching in the fields of production and automation technology and indirectly for the application-oriented investigation of business processes. Essentially, the laboratory consists of three production cells (a lathe, a 3D printer and a milling machine), a material flow system, an assembly robot and other industrial robots that connect the production cells and the assembly robot with the material flow system. All components are equipped with computer systems so that they know their own status and can communicate with other components and services. Services such as order management, energy management and quality monitoring monitor central tasks of the production system. Production control itself takes place via an agent-based system using decentralised scheduling. Additional data obtained from the Internet, such as material and energy prices, are taken into account during planning. An important aspect of the research in the laboratory is investigating the role of employees in such an environment. The central object of investigation here is how information and communication technology can be used to make work easier for employees.