Sustainability has long since become a decisive factor for the success of industrial value creation. Companies are faced with the challenge of harmonising ecological responsibility, economic efficiency and technological innovation in the circular economy. A large part of the subsequent environmental impact of a product is already determined in the early development phase - this is where it is decided how sustainable a product actually is over its entire life cycle. This is precisely where the Decide4ECO research project comes in.

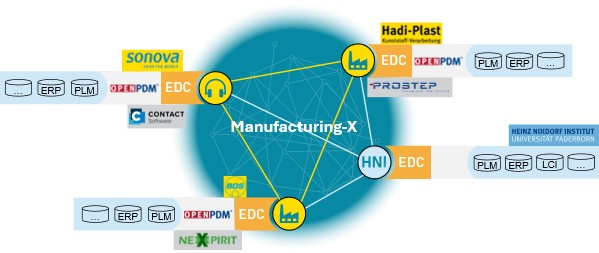

The project, which is funded by the German Federal Ministry for Economic Affairs and Energy (BMWi), aims to support product development in companies. The aim is to enable data-based, early and flexible sustainability decisions to be made in the Manufacturing-X data ecosystem. To this end, our "Product Creation" workgroup led by Prof Iris Gräßler is working with partners from the IT sector and industry to develop methods and tools that specifically promote ecological and circular value creation networks. The project is being financed with funding totalling around 6 million euros. The focus is on the question of how data can be meaningfully linked along entire supply chains and production lines in order to enable well-founded sustainability analyses.

A central starting point is the further development of existing product lifecycle management (PLM) systems. New interfaces, digital product passports (DPP) and links to data ecosystems such as Manufacturing-X are used to systematically record information on materials, energy consumption, recycled content and reparability. This information is made exchangeable across company boundaries. This enables developers to evaluate the ecological impact of material selection or system design in the lifecycle assessment (LCA) as early as the concept phase and select more sustainable alternatives.

The technological implementation of these approaches is being carried out in close cooperation between the Paderborn team led by Prof Iris Gräßler, Dr Jens Pottebaum and Sven Rarbach, the IT partners CONTACT Software, PROSTEP and Nexpirit and the industrial companies BOS GmbH & Co KG, Hadi-Plast GmbH and Sennheiser. Based on this cooperation, demonstrators are being created that show how sustainability data can be integrated into shared data spaces using standardised connectors from PLM systems. This allows key figures such as carbon footprint or product carbon footprint, recyclate quota or water utilisation to be calculated and provided flexibly. The initial results of this work have already been presented to the public - including at Hannover Messe 2025, where the project demonstrated the potential of data-based sustainability decisions. The demonstrations made it clear how digital tools for material evaluation and AI-supported analyses can be integrated into the industrial development process in order to support both ecological and economic goals.

Decide4ECO is thus creating innovative solutions for data-driven, transparent and sustainable product development. The project results are not only incorporated into industrial applications, but also into teaching at the Heinz Nixdorf Institute and help to prepare the next generation of engineers for a responsible and digitally networked industry.